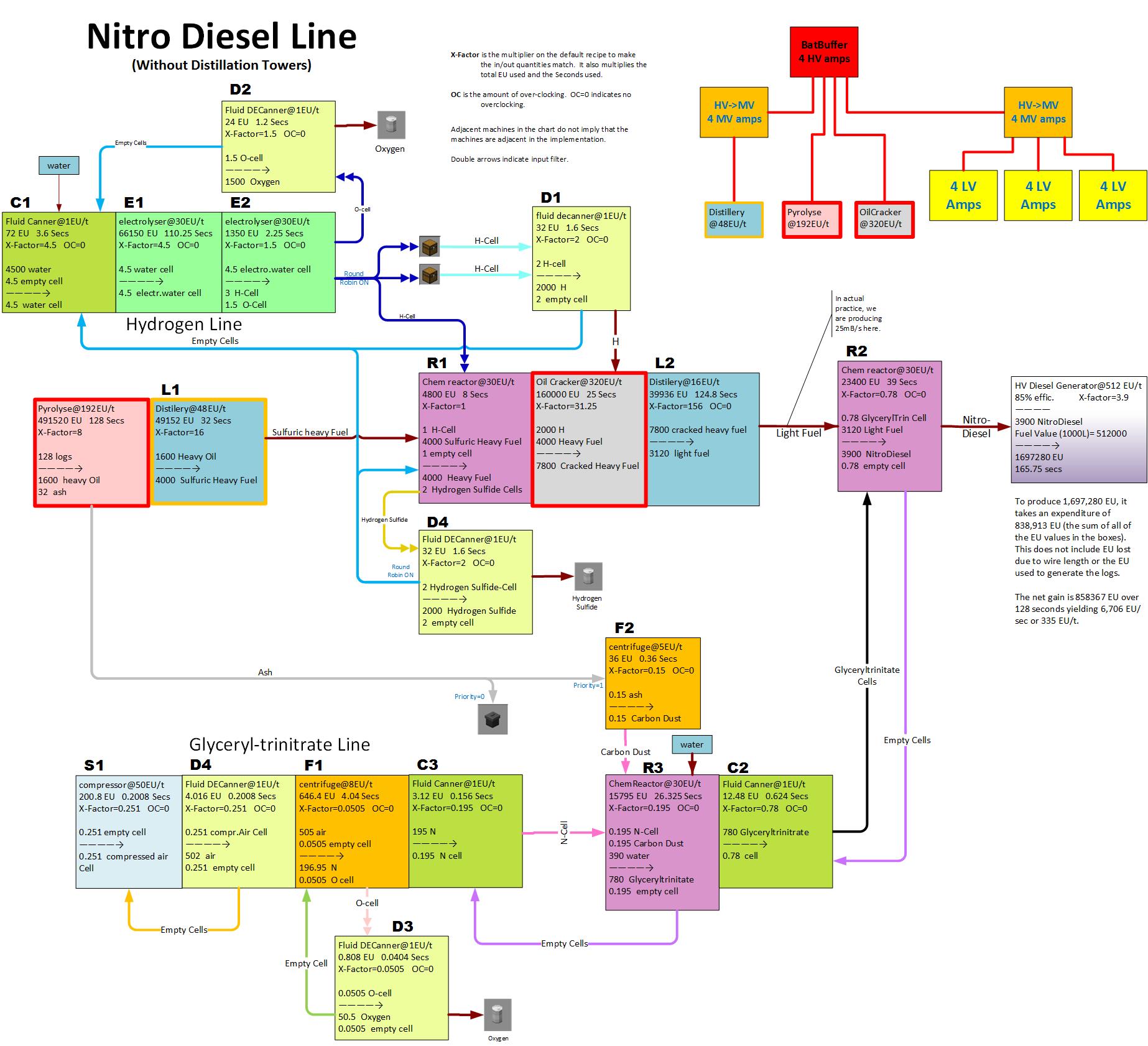

I have gotten my Nitro-diesel line built and working. I relied pretty heavily on a schematic that I built in Visio to figure out required quantities of energy, time, and material. I thought you all might find it useful when you get to this stage.

I decided to use two distilleries instead of the two distillation towers in order to keep the complexity down (so my head wouldn't explode). Thanks Joel Falk for the stuff you have put up here - it was really helpful.

Each "machine box" was created in VISIO with the NEI recipe entered as properties. Then I added am multiplication factor (X-factor) to scale the recipe up or down to fit the needed amounts of material. It also scaled the total EUs used and total amount of time required. Each box then displays the resulting figures. Its the R1 machine that has an X-factor of 1 and sets the required quantities for the rest of the chart. (That choice is somewhat arbitrary.)

The piping of items assumes using EnderIO item conduits with their ability to have filters on input, round-robin routing, and priority setting. These properties are all displayed. You will see that I have numbered the machines on the chart (and in my build with signs) so as to be able to keep track of which machine was doing what (so my head wouldn't explode). Also, I found that returning the empty-cells to the right place in the production line was crucial.

I decided to use two distilleries instead of the two distillation towers in order to keep the complexity down (so my head wouldn't explode). Thanks Joel Falk for the stuff you have put up here - it was really helpful.

Each "machine box" was created in VISIO with the NEI recipe entered as properties. Then I added am multiplication factor (X-factor) to scale the recipe up or down to fit the needed amounts of material. It also scaled the total EUs used and total amount of time required. Each box then displays the resulting figures. Its the R1 machine that has an X-factor of 1 and sets the required quantities for the rest of the chart. (That choice is somewhat arbitrary.)

The piping of items assumes using EnderIO item conduits with their ability to have filters on input, round-robin routing, and priority setting. These properties are all displayed. You will see that I have numbered the machines on the chart (and in my build with signs) so as to be able to keep track of which machine was doing what (so my head wouldn't explode). Also, I found that returning the empty-cells to the right place in the production line was crucial.