Update on Steam power

I've done some more testing in AgS 2.1.8 (Mod version 0.0.4.2fix2)

Steam is really unreliable at any sort of decent flow rate. Water will only convert to steam if it is in the bottom of the high oven tank instead of anywhere in the tank. There doesn't seem to be any way to get the steam to pull out consistently with water in the tank. I tried black listing water, and white listing steam. If fluids are added to the high oven, they always appear on the bottom of the tank. This means that if you have water appear while you are removing steam, it will stop the tank from outputting steam. Clicking on the steam will place it on the bottom of the tank and cause it to output properly. Also, if there are more than 100 buckets of water in the tank, it will not convert to steam (This was in a 7 high oven--not sure if height comes into play or not). So make sure it stays below that.

If fresh water stops being added to the tank, the entirety of the water will convert to steam and can then be pumped out of the high oven.

So, I figured out how to rig a timer to the water supply to regularly cycle it. This will let the water in the high oven internal tank sit without any additional water being added and allow all the water to convert to steam and be pumped out. The problem I ran into with this and fluiducts is that the water is still clearing from the pipe and entering the high oven while the steam output is supposed to be going on. A solution to this is to connect two input ducts. It allows the water to flow into the high oven faster and clear the pipe. With no new water being added to the system, it will all convert to steam and export to your steam consumer. (This lets you use a simple 2 state clock with even cycle periods.)

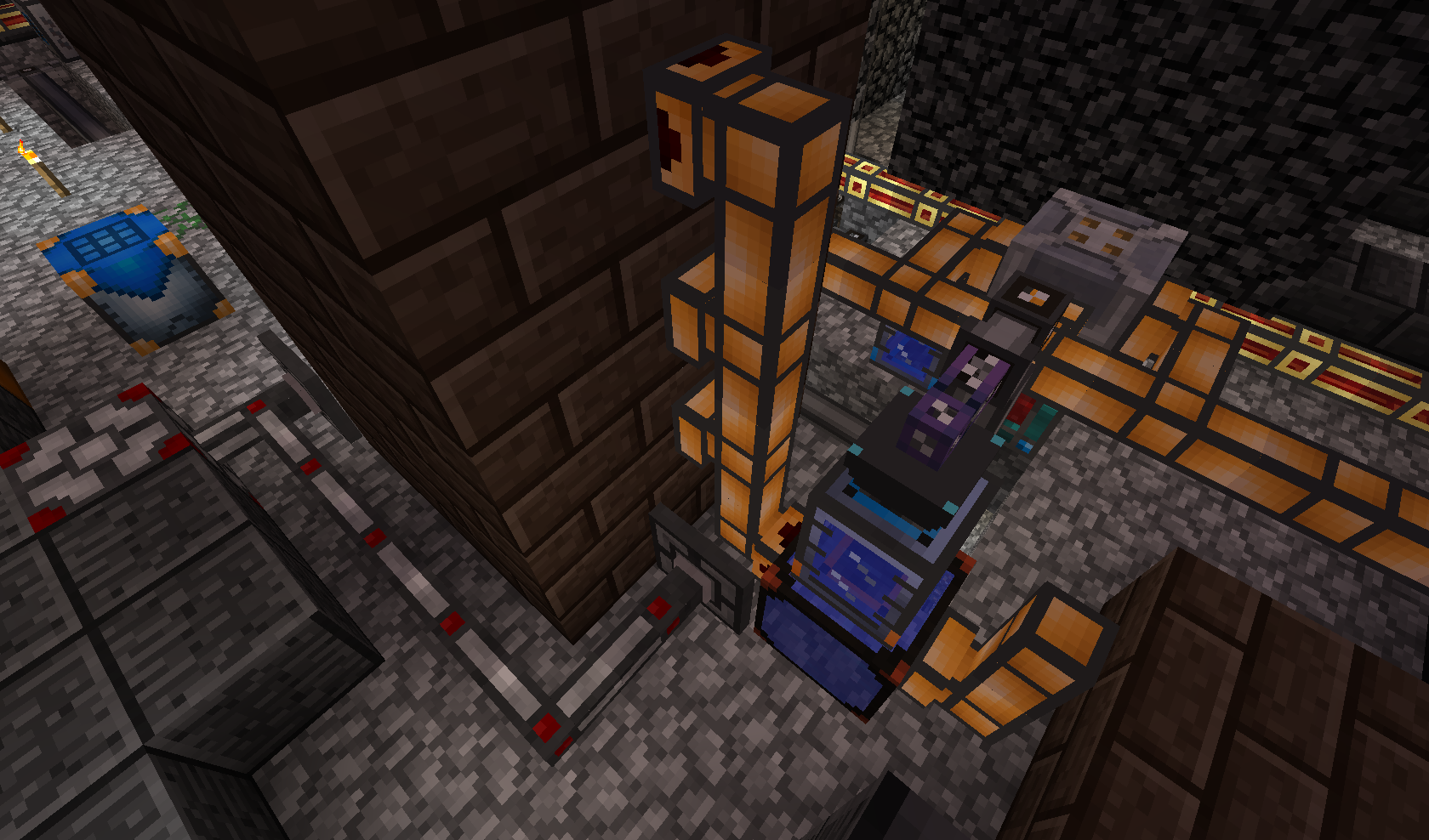

this was my testing setup so it was rather messy. You need a water tank of some sort. Connect fluiducts feeding two inputs to the high oven. Keep the fluiduct between the tank and the high oven as short as possible. You do not want a lot of water in this duct as it all has to clear before steam can be pulled out. (ignore the top connection. It was there for testing.)

I set my timer to 60 ticks. During that 60 ticks, water is being pumped into the fluiduct. While off for 60 ticks, water clears the pipe and is converted to steam, then pulled out of the high oven.

If you configure 2 high ovens this way with an inverter on the output, the ovens will cycle between themselves thereby evening out the steam output. Because you want to make sure *all* the steam leaves the high oven, you will want to over build your steam consumer, so you will never reach full capacity as you do not want steam to backup in the high oven. A backup in the system will cause it to stop functioning.

If you have multiple power systems, you will want this one to be the primary source of power, and enable additional engines and power plants as necessary.

If you have water in your AE system and can provide the water directly, this works even better!

A single connection using the 250mb/tick setting pumps 15 buckets of water in the high oven in the cycle time. It all converts to steam and will over supply a single steam turbine from MFR. If using the MFR turbine, you will need 2 of them when using AE to supply the water. Do not use the 1000mb/tick setting. It will completely fill the high oven with water, and you will have to break the high oven controller to reset the system. (and go through the reheat process again.)

By the looks of the steam production rates, you will produce just shy of enough steam to supply 3 MFR turbines completely. This should be a perfect design option. As long as the power has a place to flow, you should never backlog the system.

After I move this from my testing area to my production location I will create some better instructions and pictures, but this should be enough to get things moving.

(As a side note, the height of the oven doesn't seem to impact the steam creation although you will want to make sure it reaches the 1300 degrees required before adding your water.)