I'm probably not doing it very efficiently, as I am piping the steam to steam dynamos rather than using it with turbines, so I don't know the RF output. I have my water input tied to a redstone clock. Each oven has three water input points, and 9 steam output points. The ovens fill with water for a period of time, then stop filling for the same amount of time so that all the water turns to steam and the steam drains out.

Show Your Agrarian Skies world

- Thread starter Matul

- Start date

-

The FTB Forum is now read-only, and is here as an archive. To participate in our community discussions, please join our Discord! https://ftb.team/discord

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Okay. Since it is harder to adjust for steam use efficiency between the dynamo, Mfr turbine, and big reactors turbine, I will say my setup is producing about 120 buckets of steam every 60 ticks. (In the mfr turbine, a bucket of steam is worth 2000RF. ) I am using this as my main power plant for my entire base.

My setup is working, but still not quite the simplest thing to set up, nor have work 100% of the time. It is mainly on world loads that I had issues, but I haven't had any since I added a chunk loader and lengthened my timer a couple ticks. I am sure there are better options and methods to improve upon my design, which is why I am so interested in seeing your setup.

I wrote a tutorial once on how to setup a high oven to produce steam, but have since discovered not everything worked exactly as expected while using it in the real world. I really need to take what i have learned in running it and rewrite my guide from scratch.

My setup is working, but still not quite the simplest thing to set up, nor have work 100% of the time. It is mainly on world loads that I had issues, but I haven't had any since I added a chunk loader and lengthened my timer a couple ticks. I am sure there are better options and methods to improve upon my design, which is why I am so interested in seeing your setup.

I wrote a tutorial once on how to setup a high oven to produce steam, but have since discovered not everything worked exactly as expected while using it in the real world. I really need to take what i have learned in running it and rewrite my guide from scratch.

I will do a detailed post later, but I figured out a way to measure my steam output. Since my water input is on and off for equal amounts of time, and all the water is converted to steam, the steam output per tick is going to be equal to 1/2 the water input rate. My multimeter says water inputs at 120 mB per tick, so with my three input points, my steam generation per oven should be 180 mB per tick (so, only 10.8 buckets per 60 ticks, compared to your 60 bucket per oven estimate). Using my setup, to get 1 bucket per tick out of an oven, I would need to use 17 water input points, and probably over 50 steam output ducts to keep it running.

Now I am very curious how you have yours set up.

ETA: Based on some simple calculations, I suspect that the maximum steam production rate from a single oven should be 1620 mB per tick. This would require a very fast clock to make sure you don't load in more water than the oven can handle at a time.

Now I am very curious how you have yours set up.

ETA: Based on some simple calculations, I suspect that the maximum steam production rate from a single oven should be 1620 mB per tick. This would require a very fast clock to make sure you don't load in more water than the oven can handle at a time.

Last edited:

I will do a detailed post later, but I figured out a way to measure my steam output. Since my water input is on and off for equal amounts of time, and all the water is converted to steam, the steam output per tick is going to be equal to 1/2 the water input rate. My multimeter says water inputs at 120 mB per tick, so with my three input points, my steam generation per oven should be 180 mB per tick (so, only 10.8 buckets per 60 ticks, compared to your 60 bucket per oven estimate). Using my setup, to get 1 bucket per tick out of an oven, I would need to use 17 water input points, and probably over 50 steam output ducts to keep it running.

Now I am very curious how you have yours set up.

ETA: Based on some simple calculations, I suspect that the maximum steam production rate from a single oven should be 1620 mB per tick. This would require a very fast clock to make sure you don't load in more water than the oven can handle at a time.

Well, I'm at 1025 mB/tick with my setup right now. If it is possible to squeeze a few more ticks out of the water fill cycle and you could get the clock down to 50 ticks instead of the 55ish I'm at, this would up the average steam generation to 1200 mB/tick. Based on the mechanics of the water to steam conversion and my current setup, I don't think it is possible to get much faster than that.

Being the well written and low lag multi-block that it is, the high oven does not check to see if it can turn the water into steam every tick. Instead, it only seems to check every X ticks. I'm not quite sure what that count actually is, but it appears to be 10 ticks. So, every 10 ticks it checks to see if no more water is being added to the tank, it will then convert the water to steam, which itself takes a couple ticks, but is darn near instantaneous. If your water input cycle ends on tick 9, tick 10 sees the input as done, then will convert to steam almost instantly. However, if you cycle ends on tick 10, water is still being added at that point, so the high oven checks again in 10 ticks and then start converting the water to steam on tick 20. After the steam is produced, the steam is then pulled out and sent to your steam consumer. With my current setup my the steam conversion and export is running at 36 ticks optimally, but I've found 38 to be a bit more reliable. If we say the water to steam conversion time takes 5 ticks, this would make the time to check, then convert anywhere from 5 ticks to 15 ticks in length (or about 1/2 second discrepancy) that has to be accounted for in your timer setup. If you could somehow align the clock with the update frequency of the high oven, it would be possible to shave up to 10 ticks off this section of the timer and increase your throughput, but I don't know how that would be done though.

Since your post the other day, I've been thinking again on how to increase my overall throughput as I've gotten into gendustry and need a lot more power. I think I may have a method to do so now. I will do some experimenting tomorrow and post my findings. I've done some some preliminary calculations, and if it all works, I should be able to increase the steam throughput from 1025 mB/tick to 1209 mB/tick. The RF generation would increase from about 2050RF/tick to 2418RF/tick--about a 20% improvement.

Wow! How many steam drains do you have to get the steam out before the next batch of water comes in?

Wow! How many steam drains do you have to get the steam out before the next batch of water comes in?

Actually, I've found the water input to be the much slower part. I currently have 25 fluiducts pulling from reservoirs, emptying into the high oven with 40 fluiducts (so the ducts drain out all of their water faster), and exporting the steam via 7 fluiducts. I just used the multimeter to check throughput, and based on that, water moves at 120mB/tick, and steam moves at 360mB/tick. It appears that steam moves about 3 times faster than water through fluiducts. Now that I have some more numbers, I'll recalculate my drain ratio for water and steam and see what I can do to maximize the efficiency.

Thanks for posting this. I went the other route, minimizing the time the water takes to tun by maximizing the amount of mycellium around the barrels [9 barrels in a 7x7]. It may take the same amount of time but your way seems quicker since you're actually moving and not spinning in circles.I wanted to get enough nether quartz for the initial AE build. Sludge burner wasn't making soul sand fast enough, didn't want to go back to the Nether and dig it so I threw this together. There is a line of mycelium underneath the liquiducts. I take a stack of sand, stand on top of the barrels and just go in a circle from one barrel to the next turning the sand into soulsand. The line is big enough that the water refills and is turned to witch water by the time I get back to a particular barrel.

In that case, I will do a detailed post on how mine is set up this weekend.

I derped quite a bit. I'm still producing almost 60 buckets of steam every clock cycle, but it is 60 combined, not per oven. I goofed on the clock itself. The clock period is on for the length of time set, then off for an equal amount of time. I was thinking that it was cutting the time in half for some reason.

Oh well. I was still producing a bunch of steam, and still powering my whole base off of it, so it worked.

I am using an MFR rednet controller to run everything. Before, my thinking was to have the rednet turn the water source on and off, then throw massive amounts of fluiducts to drain all the water out of the ductwork. Instead, I realized that you can keep the duct work full of water at all times, but just enable and disable the filter. To do this, you need to add servos to all the drains that will be supplying water. Normally when adding servos and filtering fluiducts, you place the redstone control in the ignored mode. In this case however, you want the filter set to high.

This allows you to cut the water off instantly when you remove the redstone signal. You no longer have to wait for the water to drain out of the duct work. This will shorten the ticks needed for water supply mode.

The steam extraction ducts are set up as normal with the servos configured for blacklisting water, or whitelisting steam, and redstone set to ignored.

Next, you simply attach MFR rednet cable to all of the fluiducts connecting for the water supply.

When the ducts receive a redstone signal, they let water into the high oven, and when the signal is removed, they stop inputting water, and start the steam conversion. Once the steam is generated, the fluiducts set for whitelisting steam, automatically pull out the steam and send it to your power generator.

The high oven can hold 20,000mB of fluid per ingot space inside. For a 3 high oven, this is 20,000mB. For an 8 high oven this is 120,000mB. Even though this much fluid can be placed in the high oven, steam conversion stops working if it is more than 1/2 full. For a 3 high oven, this is 10,000mB. For an 8 high oven this is 60,000mB. Since I am working with an 8 high oven, I need to keep the amount of water in it to 60,000mB or less.

Water will move through a fluiduct at a rate of 120mB/tick. Steam moves 3 times as fast with a rate of 360mB/tick. Here are some calculations with the number of ticks, the flow rate, and the total volume moved.

Water

Code:

Ticks Flow rate number of drains Total volume

10 * 120 * 50 = 60000

11 * 120 * 45 = 59400

12 * 120 * 41 = 59040

13 * 120 * 38 = 59280

14 * 120 * 35 = 58800

15 * 120 * 33 = 59400

16 * 120 * 31 = 59520

17 * 120 * 29 = 59160

18 * 120 * 27 = 58320

20 * 120 * 25 = 60000Steam

Code:

Ticks - Flow Rate - Drains - Total volume

9 * 360 * 18 = 58320

10 * 360 * 17 = 61200

10 * 360 * 16 = 57600

11 * 360 * 16 = 63360

11 * 360 * 15 = 59400

12 * 360 * 14 = 60480

13 * 360 * 13 = 60840

13 * 360 * 12 = 56160

14 * 360 * 12 = 60480

15 * 360 * 11 = 59400

16 * 360 * 11 = 63360

16 * 360 * 10 = 57600

17 * 360 * 10 = 61200

18 * 360 * 9 = 58320

19 * 360 * 9 = 61560

20 * 360 * 8 = 57600Using the numbers above, I maximized the amount of water vs the time vs the number of drains. With an 8 high oven, this turns out to be a time of 13 ticks, with 38 drains for water. This gives the absolute largest amount of water in the oven without going over the 60,000 mark. With the amount of space left over, 16 drains for steam output matched the best. This number is a little less important, but does affect the overall timer used with the oven. 16 drains for steam would reach the 11 tick mark.

To make use of this properly will require a MFR rednet controller. The first thing to set is the timer. I start the value out at 60, then go from there. Next, feed the timer output to a one-shot pulse, then to a pulse lengthener. This will decouple the on and off periods from each other allowing you to independently set the water input ticks. The pulse lengthener adds ticks to the 1 tick pulse, so make sure to subtract 1 from the numbers in the sections above. Next, AND the lengthened pulse output together with a lever so you can turn it on and off. The water will only flow into the high oven if both the clock timer is on AND the lever is in the on position.

Using these numbers, I was able to improve on my overall design and reduce the overall cycle from 112 ticks (timer set @ 56) to 80 ticks (timer set @ 40). This gives a 40% improvement over my previous numbers. I tried reducing the timer to 38, but after a minute or two of running one of the cycles couldn't complete in time and the oven filled up with water.

Previously, I generated 535mB of steam/tick. The new design generates 742mB of steam/tick. This works out to 1071RF/tick previously and 1482RF/tick now. (Actual RF increase of 38%)

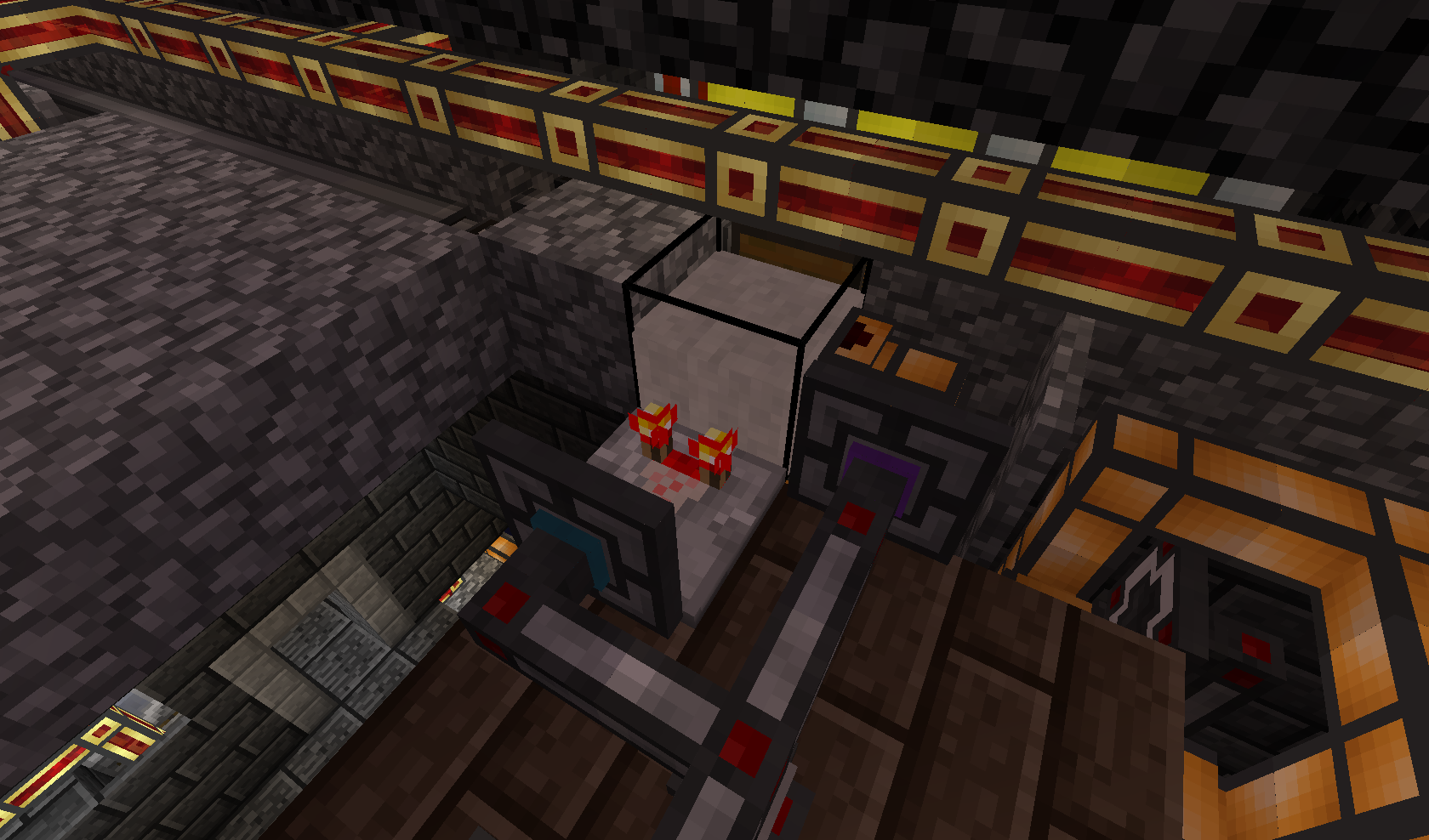

Here is the front face of my test oven. The void drain is for when I got the timing wrong and filled up the oven with water, I had a way of draining the high oven without breaking the oven and having to re-heat it again.

Nice work! I am still a newb when it comes to mods, so I had my clock set up using traditional redstone, which does not allow for the level of precision you are getting.

I am wondering if you could increase the efficiency without increasing the failure by having the fill-rest cycle regulated by the steam drainage, such that the fill cycle is triggered when the steam starts draining from the oven. Are any of the fluid storage blocks readable by comparators?

Edit to add:

Some additional derived principles of steam oven design:

In order for the water fill rate to match the fill drain rate, you need 3 water inputs for every steam output. This puts a theoretical upper limit on an 8 tall oven of 84/28.

No perfect 60000 mB fills above 50 drains matches a whole tick. 84 drains just overshoots a six 6 tick fill, and so would need to be run at 5 ticks. 83 is promising for a 6 tick cycle, as it fills to 59760.

I am wondering if you could increase the efficiency without increasing the failure by having the fill-rest cycle regulated by the steam drainage, such that the fill cycle is triggered when the steam starts draining from the oven. Are any of the fluid storage blocks readable by comparators?

Edit to add:

Some additional derived principles of steam oven design:

In order for the water fill rate to match the fill drain rate, you need 3 water inputs for every steam output. This puts a theoretical upper limit on an 8 tall oven of 84/28.

No perfect 60000 mB fills above 50 drains matches a whole tick. 84 drains just overshoots a six 6 tick fill, and so would need to be run at 5 ticks. 83 is promising for a 6 tick cycle, as it fills to 59760.

Last edited:

Nice work! I am still a newb when it comes to mods, so I had my clock set up using traditional redstone, which does not allow for the level of precision you are getting.

I am wondering if you could increase the efficiency without increasing the failure by having the fill-rest cycle regulated by the steam drainage, such that the fill cycle is triggered when the steam starts draining from the oven. Are any of the fluid storage blocks readable by comparators?

Edit to add:

Some additional derived principles of steam oven design:

In order for the water fill rate to match the fill drain rate, you need 3 water inputs for every steam output. This puts a theoretical upper limit on an 8 tall oven of 84/28.

No perfect 60000 mB fills above 50 drains matches a whole tick. 84 drains just overshoots a six 6 tick fill, and so would need to be run at 5 ticks. 83 is promising for a 6 tick cycle, as it fills to 59760.

I wanted to see what I could do to max everything out using fluiducts, so I replaced every block with a drain. There are 66 blocks total in a max size high oven. I have 1 drain for a water purge, 1 block for the controller, 1 bock for adding fuel. This leaves 63 blocks that can be drains and dedicated to water or steam.

I added another page in the mfr controller to do a separate pulse lengthener, and I have this controlling a single drain, while all the other drains are controlled by the main. This gave me 45 drains running @ 11 ticks for a total of 59400mB plus an additional drain running for 5 ticks for 600mB for a grand total of 60000mB. This left 17 drains for steam output.

With this setup, I was able to shave a single tick off the timer, so now the clock is set at 39 ticks instead of 40 ticks. This gives a grand total of 60,000mB of steam produced over 78 ticks. (Just a hare over 769 mB of steam/tick.) This will produce a bit over 1538RF/tick. So there you have it. The max output of a high oven using fluiducts is 1538RF/tick (using the MFR steam turbine).

It may be possible to make a clock-less system if you had a method of reading the fluid level inside the high oven tank, then starting the water fill cycle based on the tank being empty. Then it wouldn't matter how much time it took to convert the water to steam as the system would start automatically as soon as it was ready. Without that capability, I think what I have done is the best you can do using fluiducts.

Edit: I just determined that the openblocks tank is compatible with comparators. A single bucket of fluid will give a 1 reading. It should be possible with this to connect the tank to a single steam duct output, then read when the level drops to 0 in the open blocks tank. The tank would be empty, and by association, the high oven too, and the next water cycle could start.

Last edited:

With drains on corners, you can have a fluiduct on each face. The graphical representation of a hole is irrelevant to the function of the fluiduct.

So, an 8x3x3 high oven has 114 block faces. 84 water input points, 28 steam output points, and 1 face for the controller, 1 face for fuel input maxes it out at 114.

So, an 8x3x3 high oven has 114 block faces. 84 water input points, 28 steam output points, and 1 face for the controller, 1 face for fuel input maxes it out at 114.

With drains on corners, you can have a fluiduct on each face. The graphical representation of a hole is irrelevant to the function of the fluiduct.

So, an 8x3x3 high oven has 114 block faces. 84 water input points, 28 steam output points, and 1 face for the controller, 1 face for fuel input maxes it out at 114.

I did not know that the hole for the drain didn't matter.

I was able to rig a completely clockless design. I'm not sure how much steam it is actually producing, But it by itself is doing more than both of my previous ovens combined.

I have a single steam export duct separated from the rest and feeding the bottom of the open blocks tank. When there is fluid in the tank as read by the comparator, I have a delay before it signals the export (yellow rednet face) to start pulling the fluid out. (This allows fluid to build up in the tank to actually have something to read.) Once the tank is completely empty, it then signals the water to start filling up again. The only thing needed to kick off the whole thing is a bucket of steam in the tank. It will prime the system and get everything running automatically from then on.

I measured the throughput feeding into my resonant energy cell, and it is reading between 1903 RF/tick at the lowest to 2150 RF/tick at the highest. Most reading seem to be about 2040 RF/tick. I'm sure by using all the faces, this could be increased a bit more, but this is still pretty awesome.

Edit: Just realized that this design will completely self regulate unlike the clock design. If you over-produce steam for your needs, eventually it will back everything up due to no space for steam, that is fine. The regulator tank will not empty until there is space in the system for its steam. If the tank is not empty, the next cycle will not start. As soon as you use some power and/or steam, the tank will empty and the next cycle will start.

Edit2: I found that additional conduit connections to shave additional ticks off the fluid transfer don't help the throughput. There is no difference in my setup using 38 inputs vs 71 inputs for water and between 16 outputs vs 22 outputs for steam. The only difference is that it is a lot more time consuming to set up. The power output still hovers around 2000 RF/tick.

Last edited:

I have made some additional discoveries regarding High Oven design. While the book says there is "no reason" to make a high oven taller than 8 blocks, taller ovens do give increased capacity. They also give additional surface area for drains, but the surface area to volume ratio decreases, so that may not be important. It seems that the only things that seem to max out are the temperature and the smelting slots.(ETA: Temperature continues to scale up -- is steam production dependent upon a simple threshold, or would increasing the temp increase the conversion rate?)

This means that High Ovens are highly scalable for steam production. Whether this would be more or less efficient than building an additional steam oven is not yet clear to me.

This means that High Ovens are highly scalable for steam production. Whether this would be more or less efficient than building an additional steam oven is not yet clear to me.

Last edited:

The temperature to make steam is 1300 degrees. Beyond that, there is no difference.

One thing I have noticed is that there seems to be a slight pause when the oven is filling. Right around 29k mB with my setup. This may be where the oven does its check to covert to steam. It may be worth while to try and constrain the input so it fits inside this window.

As far as making the oven higher than 8 blocks. I am pretty sure most don't have the room to make a much taller multiblock in their base, but I admit, it does bear some additional investigation.

One thing I have noticed is that there seems to be a slight pause when the oven is filling. Right around 29k mB with my setup. This may be where the oven does its check to covert to steam. It may be worth while to try and constrain the input so it fits inside this window.

As far as making the oven higher than 8 blocks. I am pretty sure most don't have the room to make a much taller multiblock in their base, but I admit, it does bear some additional investigation.

It is lovely to see what other ppl accomplish. I have often looked at other peoples designs and solutions when I have accountered problems.

Well, this time I share my world with you, so that you can look at what not to do, or maybe get some inspiration. I am very much an "If the shit fits, wear it" person, so looks is not the main issue for me. But hopefully it will be beautiful in the end

http://imgur.com/gallery/yg0sr/new

Best regards

Roland

Well, this time I share my world with you, so that you can look at what not to do, or maybe get some inspiration. I am very much an "If the shit fits, wear it" person, so looks is not the main issue for me. But hopefully it will be beautiful in the end

http://imgur.com/gallery/yg0sr/new

Best regards

Roland

Well...been playing AS this July, and now I'm going on holidays, and after that I don't think I'll have much time to play Minecraft anymore, so I figured i'd just post here what I did during this month. Completed nearly all the quests, pretty much just lacking the dirt one (and the ones that quest opens) and the XU one. I might continue with it a bit but don't think there'll be major changes.

I'll just put a general shot and then link to an album,

http://imgur.com/a/3zhRO

The idea was to have a valley-like place, with a tall ring of ground around it. Maybe even some walls on top of the mountains for defense or whatever. But, as you can see, not much of the mountain was finished. Anyway, hope you like it and tell me what you think!

I'll just put a general shot and then link to an album,

http://imgur.com/a/3zhRO

The idea was to have a valley-like place, with a tall ring of ground around it. Maybe even some walls on top of the mountains for defense or whatever. But, as you can see, not much of the mountain was finished. Anyway, hope you like it and tell me what you think!

Well...been playing AS this July, and now I'm going on holidays, and after that I don't think I'll have much time to play Minecraft anymore, so I figured i'd just post here what I did during this month. Completed nearly all the quests, pretty much just lacking the dirt one (and the ones that quest opens) and the XU one. I might continue with it a bit but don't think there'll be major changes.

I'll just put a general shot and then link to an album,

http://imgur.com/a/3zhRO

The idea was to have a valley-like place, with a tall ring of ground around it. Maybe even some walls on top of the mountains for defense or whatever. But, as you can see, not much of the mountain was finished. Anyway, hope you like it and tell me what you think!

FTFY

I've always had issues with MFR rednet and high oven steam generation upon world load. Depending on where it was in its cycle, it would sometimes overfill the high oven with water, and I would have to manually purge it to get it all working again. Sometimes I would forget to check it when I started up my single player world, and my entire system would shut down when the REC ran out of reserve. I've finally figured out a way to detect the lack of steam, and automatically purge the high oven as needed. Now, the system runs completely automatic without any input from myself.

The open blocks tank is attached to the steam output line so it will fill with steam as it is exported by the high oven. Every 2 seconds, the purple duct will pulse for 4 ticks, and pull a tiny bit of steam out of the open blocks tank. This is normally quickly replaced by steam coming from the high oven. However, if the high oven is over-filled with water, steam will stop being produced, and this open blocks tank will eventually empty. When the tank is empty, it signals my purge valve (fluiduct with a white list for water that runs into a void block) to run for 4 seconds. Because this open blocks tank is looped in on itself, when the purple valve is activated, it will pull the same bit of steam around and around, and when it stops, a tiny amount of steam will be in the tank, and cause the comparator to switch on momentarily. This toggle will keep the 4 second water purge happening until water is below the 60 bucket limit in the high oven and steam production resumes.

This probably isn't the most graceful options, but it was the only one I could think of.

Here are a few more pictures of the high oven and piping.

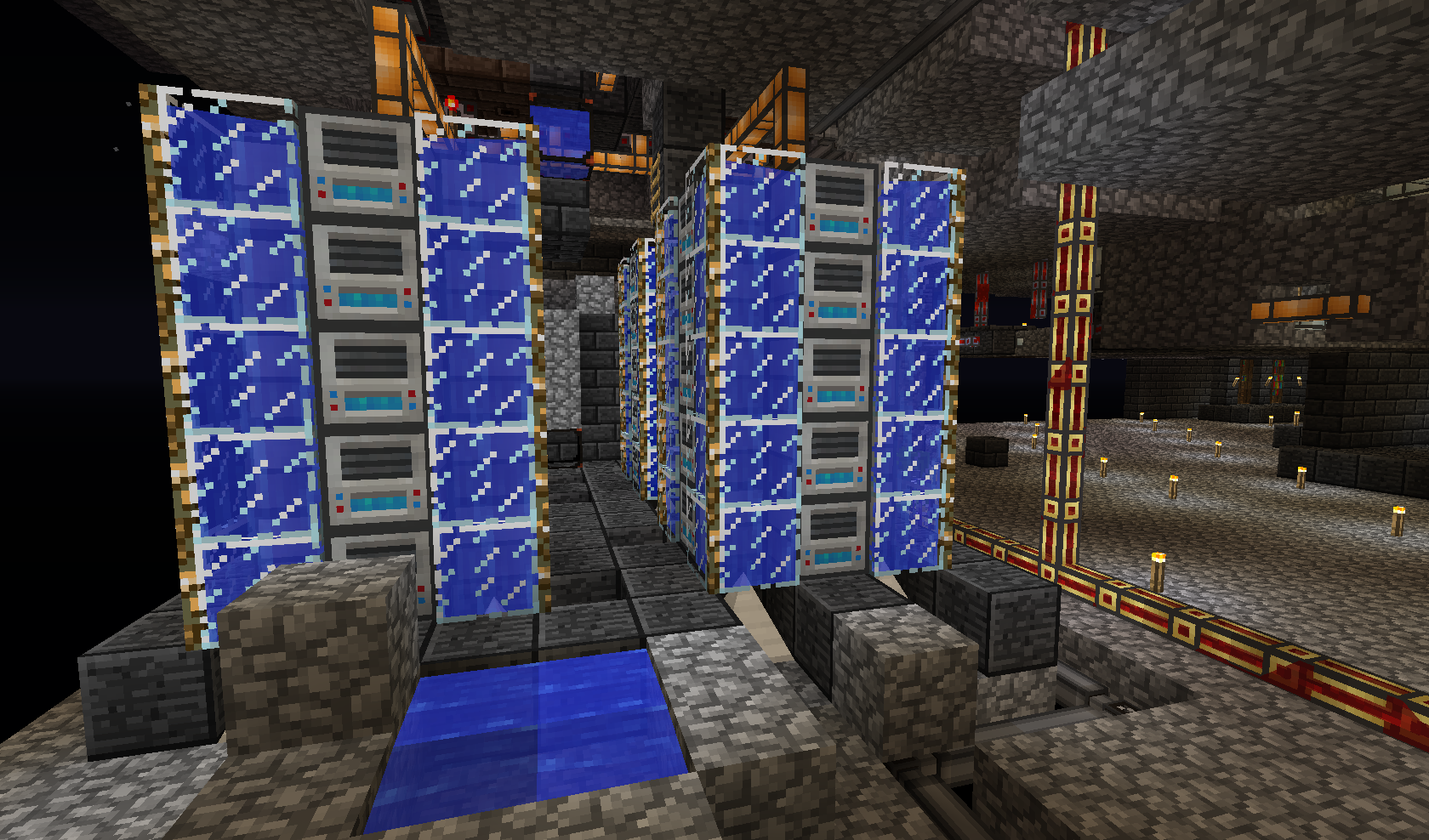

And finally, the water generation that makes all this possible. 4 "towers" of 20 aqueous accumulators each. Each tower provides about 31 buckets of water per cycle, and I need 120 bucket of water to run both high ovens at full steam. (Pardon the pun.)

And yes, those are invar spikes at the bottom of the water chambers. I'm below y=64 here, and I will get random squid spawning in the water columns. The invar spikes are there to take care of the squid. I will be adding vacuum hoppers in the middle of each tower to suck up any drops.

I will be adding walls and prettying up the rooms, but I haven't gotten that far yet. It's taken a while to set all the stuff up. I probably would be better off with a big reactor now, but I wanted to see how automated I could make this. The two high ovens running a clock-less design churn about 4k RF/tick total. (Using MFR steam turbines.)

Edit: well, the loop thing worked while testing, then failed on an actual world load. I am going to have to change it over to an SR latch instead. When the tank is empty, it turns on the SR latch, then the moment any steam get added to the block it turns back off.

The open blocks tank is attached to the steam output line so it will fill with steam as it is exported by the high oven. Every 2 seconds, the purple duct will pulse for 4 ticks, and pull a tiny bit of steam out of the open blocks tank. This is normally quickly replaced by steam coming from the high oven. However, if the high oven is over-filled with water, steam will stop being produced, and this open blocks tank will eventually empty. When the tank is empty, it signals my purge valve (fluiduct with a white list for water that runs into a void block) to run for 4 seconds. Because this open blocks tank is looped in on itself, when the purple valve is activated, it will pull the same bit of steam around and around, and when it stops, a tiny amount of steam will be in the tank, and cause the comparator to switch on momentarily. This toggle will keep the 4 second water purge happening until water is below the 60 bucket limit in the high oven and steam production resumes.

This probably isn't the most graceful options, but it was the only one I could think of.

Here are a few more pictures of the high oven and piping.

And finally, the water generation that makes all this possible. 4 "towers" of 20 aqueous accumulators each. Each tower provides about 31 buckets of water per cycle, and I need 120 bucket of water to run both high ovens at full steam. (Pardon the pun.)

And yes, those are invar spikes at the bottom of the water chambers. I'm below y=64 here, and I will get random squid spawning in the water columns. The invar spikes are there to take care of the squid. I will be adding vacuum hoppers in the middle of each tower to suck up any drops.

I will be adding walls and prettying up the rooms, but I haven't gotten that far yet. It's taken a while to set all the stuff up. I probably would be better off with a big reactor now, but I wanted to see how automated I could make this. The two high ovens running a clock-less design churn about 4k RF/tick total. (Using MFR steam turbines.)

Edit: well, the loop thing worked while testing, then failed on an actual world load. I am going to have to change it over to an SR latch instead. When the tank is empty, it turns on the SR latch, then the moment any steam get added to the block it turns back off.

Last edited:

This is my Agrarian Skies survival map. There was so many maps I played before this one, but I kept restarting because I was always dying of stupid causes, like getting kicked off the edge by angry zombies inside my mob trap.

Nothing really special about this map aside from a big mob tower. I made a second level underneath for some Tinkers Construct and storage stuff.

It's not as purtified as I wanted it to look because working on projects and grindy tasks means I have little time and energy left over for making things look nice.

Nothing really special about this map aside from a big mob tower. I made a second level underneath for some Tinkers Construct and storage stuff.

It's not as purtified as I wanted it to look because working on projects and grindy tasks means I have little time and energy left over for making things look nice.