I was wondering what kind of power is easiest to generate. All of them can be converted fairly easily. When I say easiest I mostly mean most power generated in the shortest amount of time. And on a side note I really hate nuclear power, so just keep that in mind  Thanks! I'm trying to go for a complicated looking, but efficient, way to generate multiple types of energy.

Thanks! I'm trying to go for a complicated looking, but efficient, way to generate multiple types of energy.

Power Generation

- Thread starter vKILLZ0NEv

- Start date

-

The FTB Forum is now read-only, and is here as an archive. To participate in our community discussions, please join our Discord! https://ftb.team/discord

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Celestialphoenix

Too Much Free Time

Thanks! I'm trying to go for a complicated looking, but efficient, way to generate multiple types of energy.

Set up a massive boiler, you can generate MJ and Eu. they also look awesome and you get crazy fuel efficiency.

I was wondering what kind of power is easiest to generate. All of them can be converted fairly easily. When I say easiest I mostly mean most power generated in the shortest amount of time. And on a side note I really hate nuclear power, so just keep that in mindThanks! I'm trying to go for a complicated looking, but efficient, way to generate multiple types of energy.

Which is it? Easy, most power in short amount of time or complicated and efficient? It's like that old joke, you can have it fast, cheap and high quality, pick 2.

Fastest in the shortest amount of time, although you hate it, nuclear, but it's fairly complicated.

Easy but not as fast? Lava either in Magmatics or Thermal Generators.

Efficient, but slow and somewhat complicated? Farms feeding fermenter(s) then into still(s) and finally into a liquid boiler.

Which works in your situation is only something that you can decide. But as an example, I personally like the farms -> fermenters -> still -> boiler route because I prefer to have a highly efficient, constant generation of minimal power. I load up on energy storage and rely on that to get me through any fluctuations in power demand. I also tend to have back-up power generation of the "easy but not as fast" variety for when my batteries run dry and I need to up my energy production on demand. So I often also have a bank of thermal generators ready to be flipped on as needed.

Well, the reason I'm looking for a new way to generate power is because I've done quite a few setups and I want something different. I've used nuclear to death, along with solar and lava. Also I don't really like placing down one or two blocks (like HV solar panels) and instantly have enough power. I like builds that have multiple stages and are self sufficient. I was thinking of having a forestry tree farm that would make charcoal and biomass and just go from there. But not really sure yet. I might combine that with a boiler, because I haven't used them yet and they look fun.

Also I don't really like placing down one or two blocks (like HV solar panels) and instantly have enough power. I like builds that have multiple stages and are self sufficient. I was thinking of having a forestry tree farm that would make charcoal and biomass and just go from there. But not really sure yet. I might combine that with a boiler, because I haven't used them yet and they look fun.

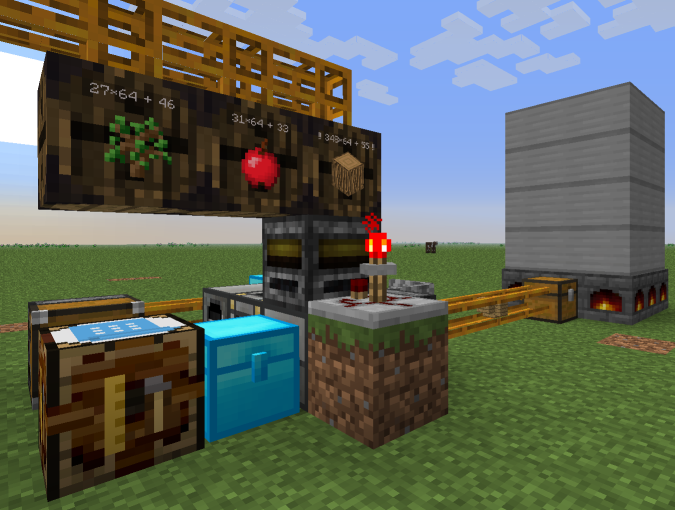

I find them quite fun. My current setup is as follows, automation is mostly Logistics Pipes, power and fluids is all TE. Also all water is fed from a single RC Tank which is filled by a TE aqueous accumulator.

Stage 1, Farms:

- 1 Forestry tree farm

- 1 Forestry cactus farm

- 1 Forestry wheat farm

- 1 poorly designed piston cane farm

- Coal from mining/quarry.

Stage 2, fuel conversion:

- I have a fermenter which takes inputs from cane, wheat, catcus and saplings via a hopper. It feeds biomass into a RC tank (RC tanks are 3x3x4 for now). That in turn feeds into a still which dumps into a RC tank.

- 1 squeezer which takes apples and outputs juice for the fermenter and mulch for the tree farm. So far this needs to be manually juggled.

- 1 squeezer for wheat seeds which outputs to another RC Tank

- 1 RC coke oven. Both outputs are automatically ejected with the oil going to a 64 bucket BC tank.

- 1 TE magma crucible that takes all my netherack and dumps into another RC tank.

- Wood is converted into charcoal on an as needed basis.

- The creosote, biofuel and seed oil are piped into a 16LP liquid boiler. I juggle the inputs manually right now, mainly to burn off the creosote when the 64B tank gets full.

- Coke is reserved for my quarry which is powered by the 3 hobbyist engines I have retired from use in my main base.

- Lava is piped into 4 TE magmatic engines which are engaged on demand when a secondary RECell becomes empty.

- Charcoal is used in 2 TE Steam engines that is also turned on as demand requires, manual operation at the moment.

- Lava is also used in TE portable tanks to power supplemental magmatic engines attached to my quarry.

There are loads of systems which are probably simpler to build and certainly systems which generate far more power. I mean I am only on a 16LP pushing 3 commercial steam engines. But it has been really fun building it up from scratch and challenging to solve all the logistics problems it presents. But not in a way that feels grindy or overly complex just to be grindy or overly complex. There's a lot of inputs to juggle and automate and each provides an incremental improvement to the system as a whole. Especially when you start juggling and automating the outputs as well.

Like I said, I find it interesting, challenging and fun. Some of the most fun I've had in Minecraft since my first map back in alpha. Might be that you'll find it interesting, fun and challenging, too?

I'm thinking of: Stage 1: mine netherrack, Stage 2: magma crucible the netherrack into lava, Stage 3: massive steam boiler, Stage 4: fall into lava while mining netherrack, Stage 5: ragequit.

Stages 1 though 3 are the plan, and stages 4 and 5 are what I expect to happen from personal experience. I guess I'll try to prevent that my making the netherrack mining an automated process.

Stages 1 though 3 are the plan, and stages 4 and 5 are what I expect to happen from personal experience. I guess I'll try to prevent that my making the netherrack mining an automated process.

The most power in the least amount of time would definitely be the Stirling engine from buildcraft. The only complex components it needs is a single piece of iron and a single piece of redstone. You will likely have plenty of coal to power it by the time you make your way down to the redstone layer.

Seriously though, you give 3 divergent requirements. Especially your easy and complicated looking requirement. Which modpack are you playing with? Most importantly, are you playing with GregTech? There are quite a few possibilities with that installed. One of the highly successful ones is to use a rubber tree farm to feed the logs to an industrial centrifuge, then use the methane cells over to a liquid transposer to "unbottle" it. The liquid methane goes to a storage tank, then feeds a RC boiler for MJ energy, or a gas turbine for EU.

You can also take the carbon cell from GT, and mate it in a GT electric crafting table along with hydrogen cells from water in the industrial electrolyser (sp?) for even more methane production.

It's simple in the fact that everything gets converted to a single fuel source, but complex in that you need multiple mid-high tier machines to complete.

You can also take the carbon cell from GT, and mate it in a GT electric crafting table along with hydrogen cells from water in the industrial electrolyser (sp?) for even more methane production.

It's simple in the fact that everything gets converted to a single fuel source, but complex in that you need multiple mid-high tier machines to complete.

When I said easiest I meant most energy generated per second pretty much. Not which was easiest like place one or two blocks and you're set. So I guess the correct term would be most efficient?

I'm using an edited version of the Mindcrack pack. I've pretty much combined the Mindcrack and DW20 packs as well as adding a few random mods I like. So what I'm getting is that the boiler is ultimately the best way to go? If so where could I find the fuel efficiency? Like how much steam would one piece of coal make, and how much MJ would that bit of steam make in the higher tier steam engine (can't think of what it's called). What I am currently considering is using tree farm and wheat farms to make biofuel, then use biofuel in the boiler. By using forestry farms I can make the entire process self sufficient (except maybe making the catalysts, because u need mined materials or bee stuff, and bees are very hard to automate). What I do is use tree farms to make wood, saplings, and apples. Wood feeds into iron furnaces which pump out charcoal. Charcoal feeds into sterling engines that power all the farms plus the machines required to make biofuel. The apples go make apple juice, apple juice plus mulch and saplings makes biomass. The wheat farm is used to produce dirt and wheat to make the humus for the tree farms. You make the dirt by sending the extra seeds to get made into plant balls, which get macerated into dirt. Then dirt plus wheat makes compost. Compost plus dirt makes humus. And bam, fully self sufficient biofuel producing factory. The only big issue is that you don't really produce enough apples to keep the squeezer going so I was thinking of either adding a second tree farm to see if that works, or setting up some way of using water when I don't have any juice. Not even sure if that's possible. Its a little overly ridiculous, but that's the way I like it. But before I waist the time and resources to make this, is biofuel a very good fuel for the boiler?

I'm using an edited version of the Mindcrack pack. I've pretty much combined the Mindcrack and DW20 packs as well as adding a few random mods I like. So what I'm getting is that the boiler is ultimately the best way to go? If so where could I find the fuel efficiency? Like how much steam would one piece of coal make, and how much MJ would that bit of steam make in the higher tier steam engine (can't think of what it's called). What I am currently considering is using tree farm and wheat farms to make biofuel, then use biofuel in the boiler. By using forestry farms I can make the entire process self sufficient (except maybe making the catalysts, because u need mined materials or bee stuff, and bees are very hard to automate). What I do is use tree farms to make wood, saplings, and apples. Wood feeds into iron furnaces which pump out charcoal. Charcoal feeds into sterling engines that power all the farms plus the machines required to make biofuel. The apples go make apple juice, apple juice plus mulch and saplings makes biomass. The wheat farm is used to produce dirt and wheat to make the humus for the tree farms. You make the dirt by sending the extra seeds to get made into plant balls, which get macerated into dirt. Then dirt plus wheat makes compost. Compost plus dirt makes humus. And bam, fully self sufficient biofuel producing factory. The only big issue is that you don't really produce enough apples to keep the squeezer going so I was thinking of either adding a second tree farm to see if that works, or setting up some way of using water when I don't have any juice. Not even sure if that's possible. Its a little overly ridiculous, but that's the way I like it. But before I waist the time and resources to make this, is biofuel a very good fuel for the boiler?

For MJ's the most efficient by far is the boiler. Since you never want to stop a boiler after you start it you often have way more MJ's than you can use so most run magma crucibles to eat up the MJ's. The crucibles make Lava which has many uses or can simply be burned in a thermal/geothermal generator for EU - which has larger storage units.

Biofuel is a good fuel. It is balanced well with the solid fuel options, so automating either is an interesting project and has a good reward.

You can get all the math for the boiler here. I am sure someone has a google spreadsheet for it as well. The formula has been tweaked the last few updates.

http://railcraft.wikispaces.com/Steam Boiler (Device)

From the page, biofuel has a heat value of 32000. The 36 tank HP boiler - using the formula on the page - a hot 36 HP boiler needs 15.84 heat a tick. There are 20 ticks a second. So one bucket of biofuel will last about 2000 ticks or 100 seconds. The boiler will generate 720 steam a tick (36 HP * 40). Using any of the railcraft engines the steam can be converted to MJ's at 5 steam per MJ, so you generate up to 144 MJ/t (720/5). The railcraft engines running on steam are all the same efficiency just higher max output. So you can use 18 industrial or 36 commercial, or 72 hobbyist and have the same 144 MJ/t. 144 * 2000 is about 290k per bucket of biofuel.

The next best place you could burn that is a combustion engine, which will only give you 6 Mj/t and output a total of 200k MJ from the same bucket of biofuel.

Many take a portion of that MJ/t and generate lava using magma crucibles. Then use the lava in thermal (gregtech) or geo-thermal generators to generate EU. EU generation is relatively balanced outside of the solar panels.

If you have gregtech methane is in my opinion the best fuel and requires minimal infrastructure. 2 industrial centrifuges and a rubber tree farm can run the biggest boiler.

Recyclers are an option as well - technically the most efficient, 18 kept fully stocked can run a 36 HP boiler.

Biofuel is a good fuel. It is balanced well with the solid fuel options, so automating either is an interesting project and has a good reward.

You can get all the math for the boiler here. I am sure someone has a google spreadsheet for it as well. The formula has been tweaked the last few updates.

http://railcraft.wikispaces.com/Steam Boiler (Device)

From the page, biofuel has a heat value of 32000. The 36 tank HP boiler - using the formula on the page - a hot 36 HP boiler needs 15.84 heat a tick. There are 20 ticks a second. So one bucket of biofuel will last about 2000 ticks or 100 seconds. The boiler will generate 720 steam a tick (36 HP * 40). Using any of the railcraft engines the steam can be converted to MJ's at 5 steam per MJ, so you generate up to 144 MJ/t (720/5). The railcraft engines running on steam are all the same efficiency just higher max output. So you can use 18 industrial or 36 commercial, or 72 hobbyist and have the same 144 MJ/t. 144 * 2000 is about 290k per bucket of biofuel.

The next best place you could burn that is a combustion engine, which will only give you 6 Mj/t and output a total of 200k MJ from the same bucket of biofuel.

Many take a portion of that MJ/t and generate lava using magma crucibles. Then use the lava in thermal (gregtech) or geo-thermal generators to generate EU. EU generation is relatively balanced outside of the solar panels.

If you have gregtech methane is in my opinion the best fuel and requires minimal infrastructure. 2 industrial centrifuges and a rubber tree farm can run the biggest boiler.

Recyclers are an option as well - technically the most efficient, 18 kept fully stocked can run a 36 HP boiler.

Okay, so I'm leaning a heck of a lot. LOL. So I'm trying to set up my automated bio fuel factory. But I'm having issues with Redpower sorting machines. I'm not sure if its possible but is there a mode on a sorting machine that pushes items row by row, but if and item from a row is missing it skips to the next one? Not sue if that makes since

you know which one it is? I've been testing it to death, but I can't figure it out. Like say I'm sorting three items. Items A,B, and C. Item A cycles through normally so the sorting machine moves on to item B. Item B has no where to go, so it gets jammed up, meaning item C never gets to cycle, and has to wait for item B to cycle. This is pretty much how it works every time. Unless I'm missing something.

Hard to describe since Elo's opposed to tool tips. So I'm left with describing tiny icons for a block I rarely use from memory. >.<

The unofficial recipe page for RP2 lists the following for the sorter. Note that this is for PR5 and new modes have been added in PR6, so it is definitely in there. What you're looking for is "allstack sequential".

The Sorting Machine enables you to set up item delivery with military precision. Like the filter it can be used inline (meaning between tubes) or connected to an inventory (usually a chest or a buffer). It will tag items with a color if you select a color using the buttons below the columns. It has five modes of operation:

The unofficial recipe page for RP2 lists the following for the sorter. Note that this is for PR5 and new modes have been added in PR6, so it is definitely in there. What you're looking for is "allstack sequential".

The Sorting Machine enables you to set up item delivery with military precision. Like the filter it can be used inline (meaning between tubes) or connected to an inventory (usually a chest or a buffer). It will tag items with a color if you select a color using the buttons below the columns. It has five modes of operation:

- In "anystack sequential" mode the slider moves from column to column and waits until it can satisfy any single item in that column.

- The "allstack sequential" mode moves from column to column pulling matches for all the stacks.

- "Random allstack" will satisfy all items in any column.

- This mode will try to satisfy any item at all, starting at the top left of an inventory.

- The last mode is like the one before, but it also provides a default color for items that match no item in any column.

(Post edited with details on the solid fuel setup)

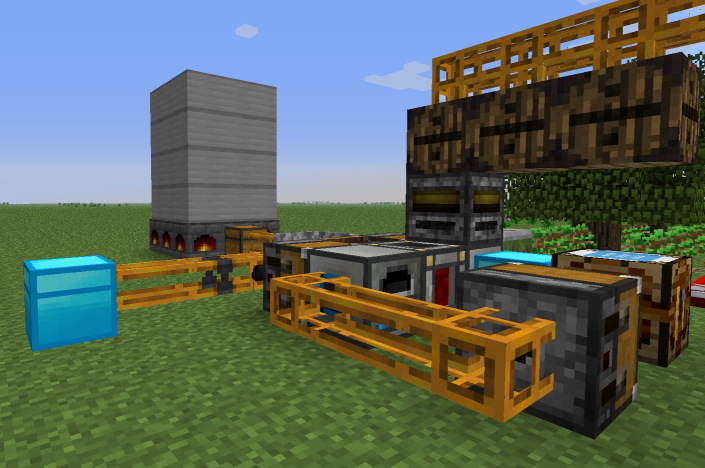

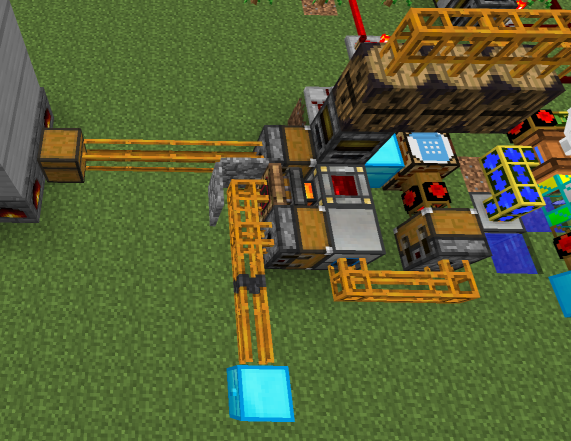

I'm currently experimenting (NEI cheat mode) with a steve's cart tree farm (16x14 track size, looks like an E) powering two 36 HP boilers.

Saplings->biomass->biofuel->liquid boiler

Logs->planks(TE sawmill)->solid boiler (even without the extra charcoal from the sawdust, this gives more heat than just burning the logs into charcoal)

The fermenter/still is fed with 44 MJ/t from the boiler, while the last 100 MJ/t are used for lava production with 5 crucibles. Those crucibles will always make a short pause between each bucket because of energy loss through the conduits (currently 48/52 feeding via REConduits into a RECell and then 100 via REConduit to the crucibles).

(Fertilizer production for the fermenter currently is not automated, will come in the future.)

For the second one:

Input from the top left from the farm.

Filter pulls every 22.7 seconds 4 logs from the barrel into the sawmill. Sawmill outputs planks (via relay) into the tube to the boiler and the sawdust into the chest in the front. Auto crafting table crafts compressed sawdust. Wooden pipe with autarchic gate pulls into relay which leads into furnace. Furnace outputs into the back via relay into tubes, which are connected to TE steam engine (powers the RECell set to 1 MJ/t which sits between the furnace and sawmill) and (via restriction tube) the second chest.

The timing of the 22.7 seconds per 4 logs only fits, when the boiler has reached 1000°C.

Beware: the solid boiler eats a plank every two ticks on a cold start.

Beware: the solid boiler eats a plank every two ticks on a cold start.

---------

For the rubber farm -> centrifuge mentioned above, I used two stacked farms mentioned in some other thread. The dirt is handled by macerating a few of the plantballs received by the centrifuging process. Rest is fermented to biomass in a biogas engine feeding the farm setup. Fertilizer for the fermenter (like above) is currently not automated.

I'm currently experimenting (NEI cheat mode) with a steve's cart tree farm (16x14 track size, looks like an E) powering two 36 HP boilers.

Saplings->biomass->biofuel->liquid boiler

Logs->planks(TE sawmill)->solid boiler (even without the extra charcoal from the sawdust, this gives more heat than just burning the logs into charcoal)

The fermenter/still is fed with 44 MJ/t from the boiler, while the last 100 MJ/t are used for lava production with 5 crucibles. Those crucibles will always make a short pause between each bucket because of energy loss through the conduits (currently 48/52 feeding via REConduits into a RECell and then 100 via REConduit to the crucibles).

(Fertilizer production for the fermenter currently is not automated, will come in the future.)

For the second one:

Input from the top left from the farm.

Filter pulls every 22.7 seconds 4 logs from the barrel into the sawmill. Sawmill outputs planks (via relay) into the tube to the boiler and the sawdust into the chest in the front. Auto crafting table crafts compressed sawdust. Wooden pipe with autarchic gate pulls into relay which leads into furnace. Furnace outputs into the back via relay into tubes, which are connected to TE steam engine (powers the RECell set to 1 MJ/t which sits between the furnace and sawmill) and (via restriction tube) the second chest.

The timing of the 22.7 seconds per 4 logs only fits, when the boiler has reached 1000°C.

---------

For the rubber farm -> centrifuge mentioned above, I used two stacked farms mentioned in some other thread. The dirt is handled by macerating a few of the plantballs received by the centrifuging process. Rest is fermented to biomass in a biogas engine feeding the farm setup. Fertilizer for the fermenter (like above) is currently not automated.

Does anyone know any tricks to up the apple juice production without simply going the "more trees" route?The only big issue is that you don't really produce enough apples to keep the squeezer going

Update Forestry and use the new tree breeding mechanics to try to get apple oak saplings to have more frequent apple drops from the leaves.