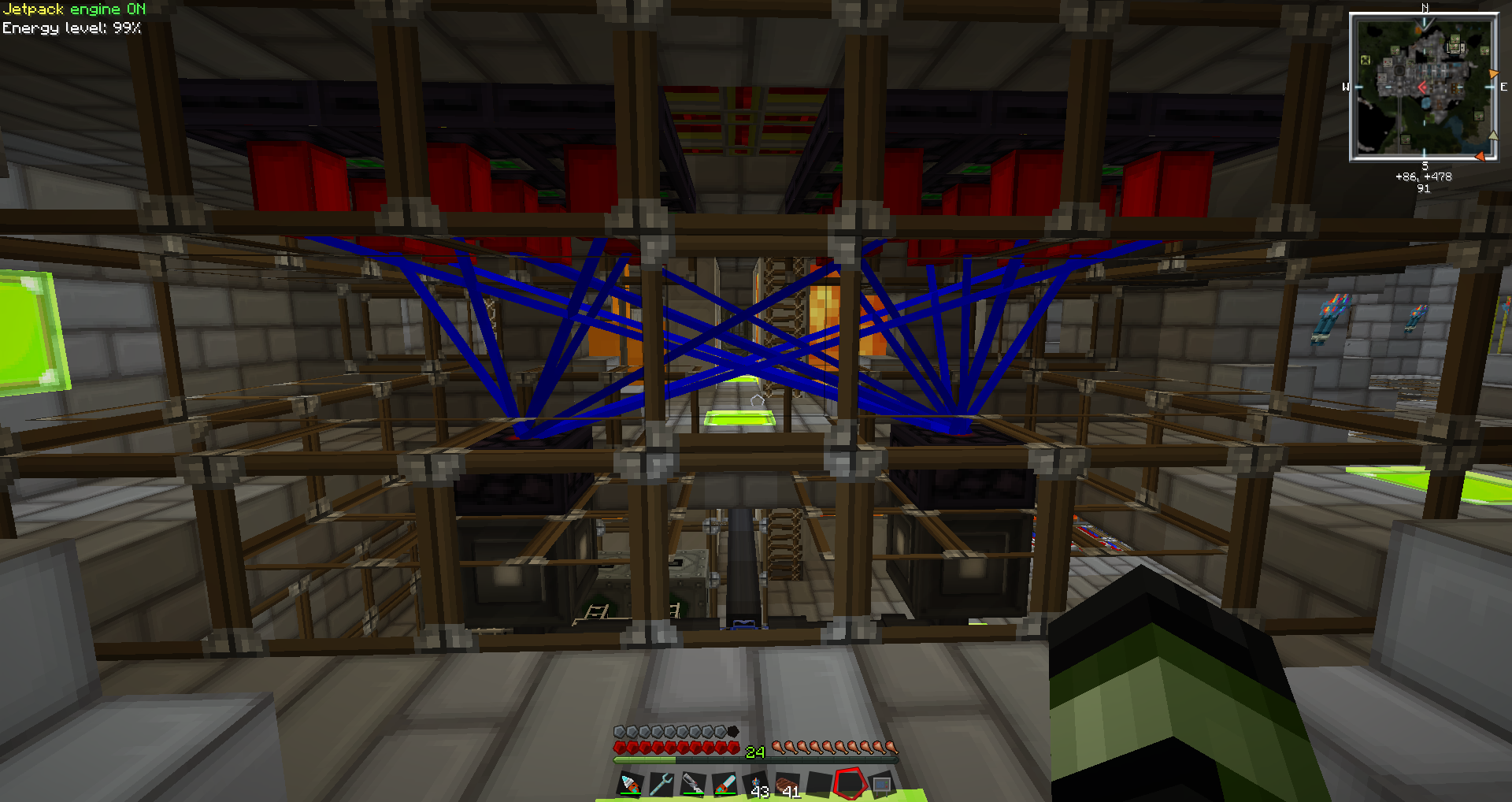

Firin' mah lasarz

- Thread starter namiasdf

- Start date

-

The FTB Forum is now read-only, and is here as an archive. To participate in our community discussions, please join our Discord! https://ftb.team/discord

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cough* https://plus.google.com/113074449898382436082/posts/MNbioAvKKiH * Cough

I think this is inefficient,since more lasers = faster

I think this is inefficient,since more lasers = faster

I know, but I needed to separate materials in order to automate it using AE. One table ONLY creates chipsets. The other make gates and pipe wire. This was my solution to allow me to request things from my AE system and let this do the rest. Since pipe wire and chip sets share the same materials, I had no way of telling the table which one I wanted, rather it would alternate between the two recipes. This would mean that my requests would never be exactly what I asked for.

Cough* https://plus.google.com/113074449898382436082/posts/MNbioAvKKiH * Cough

I think this is inefficient,since more lasers = faster

Jezus Christ man. Just... dang

I know Hack Overkilled it,but I don't care(If he didn't this,I would later)Jezus Christ man. Just... dang.

Oh,I usually just leave some at stock,I usually don't use gates THAT oftenI know, but I needed to separate materials in order to automate it using AE. One table ONLY creates chipsets. The other make gates and pipe wire. This was my solution to allow me to request things from my AE system and let this do the rest. Since pipe wire and chip sets share the same materials, I had no way of telling the table which one I wanted, rather it would alternate between the two recipes. This would mean that my requests would never be exactly what I asked for.

I am using about 300 in my base already. I keep about 200 in stock and build them 20-50 at a time.[DOUBLEPOST=1378162496][/DOUBLEPOST]The main part is automation though. I don't have to manually input items and I can be anywhere in my base when making requests.[DOUBLEPOST=1378162539][/DOUBLEPOST]Also, if I am ONLY making chipsets or ONLY make gates/pipe wire, each assembly table is in range of every laser. I can still utilize all 18 lasers on one table.

Yea a diamond chipset in just less than 4 seconds! I wonder if 300 lasers is the max you can fit in the detection radius..Jezus Christ man. Just... dang.

That's cool and all, but I just don't get what sort of setup requires that many lasers/chipsets/gates/whatever it is.

Well, a massive Molecular Assembly Chamber for example, think 8x, or 16x.

What's the biggest size MAC anyway?

Well, a massive Molecular Assembly Chamber for example, think 8x, or 16x.

What's the biggest size MAC anyway?

Oh... I've never once used an assembly table for building AE stuff... the web page does say it's cheaper, so maybe I should.

Biggest MAC, I dunno, the web page doesn't say for biggest. Only smallest size is specified, at 3x3x3.

Oh... I've never once used an assembly table for building AE stuff... the web page does say it's cheaper, so maybe I should.

Biggest MAC, I dunno, the web page doesn't say for biggest. Only smallest size is specified, at 3x3x3.

Yeah, well, that's not very interesting if you have such a laser assembly, is it?

Mine's two stacks of lasers :3.

It costs a lot more energy to use the assembly table but you do save a few raw materials. However, it takes a lot longer to make them use the assembly table as well. My 1st AE build I used a similar setup to automate AE. Every build since then I just use the MAC to create the processor needed then bake in one of the furnaces.

It costs a lot more energy to use the assembly table but you do save a few raw materials. However, it takes a lot longer to make them use the assembly table as well. My 1st AE build I used a similar setup to automate AE. Every build since then I just use the MAC to create the processor needed then bake in one of the furnaces.

P'raps, but that's nowhere as flashy

Well I just looked up the recipes for a basic processor, as an example.

Without lasers: 2 redstone, 1 silicon, 1 gold. Cook in furnace for 160MJ for 5 or so seconds.

With lasers: 1 redstone, 1 silicon, 1 gold. Cook in ass table for 30000MJ for however long, depending on number of lasers.

So... yeah. I think I'll skip the flashy on this one.

Without lasers: 2 redstone, 1 silicon, 1 gold. Cook in furnace for 160MJ for 5 or so seconds.

With lasers: 1 redstone, 1 silicon, 1 gold. Cook in ass table for 30000MJ for however long, depending on number of lasers.

So... yeah. I think I'll skip the flashy on this one.

With those 300 lasers you can get a basic proccesser in just under 1.5 seconds. Well worth it if your willing to house all those lasers.

I managed to fit 294 in on our last map, the door being 3x2 lost my last 6

I saw a video of a monstrous MAC. It's a little cheesy but you get a good sense plus actual numbers involved.

I don't think there is a max size limit...

I don't think there is a max size limit...